HARDI Saritor 62 Active

- Central Ag Equipment

- Oct 7, 2021

- 9 min read

Updated: Jan 30, 2025

HARDI Saritor 62 Active

In front of the field

SARITOR 62 Active takes a proven sprayer to the next level with a larger stainless steel tank, more power, improved comfort and advanced booms.

This uniquely Australian SARITOR is driven by a 300HP Cummins QSB 6.7 litre diesel engine, driving four Danfoss Hydrostatic wheel motors. The Cat.4 cab provides a cool, clean operator environment with fingertip controls and your choice of ISOBUS controller.

And in the field, a range of steel or HARDI PARAGON aluminium booms from 36 m to 48.5 m eat up the acres with unrivalled ride and remarkably precise height management.

Unrivalled boom ride

One of the most outstanding features of SARITOR 62 Active is its remarkable boom ride. Capitalising on HARDI’s 30+ years of experience, SARITOR uses a wide Paralift boom centre with HARDI’s AutoTerrain boom height and stability control, coupled to patented yaw dampening.

This intelligent, integrated system proactively positions the boom to proactively compensate for terrain changes.

The result is precise tip-to-tip height control, for more accurate spraying and near-zero chance of ground strikes, even with high spraying speeds and our widest aluminium booms.

ActiveAir nozzle control

The ActivAir nozzle on/off system uses SARITOR’s onboard air supply to instantly open and close nozzles on demand, with no dripping.

Solenoids along the boom ensure precise switching for spraying and AutoSection control, with short air connections from each solenoid to its nozzle(s) for an instantaneous response. Fluid recirculation maintains pressure in the boom, so nozzles spray at the correct rate from the moment they’re activated, and provides simple boom flushing and rinsing without having to empty the rinse solution into the field.

All for the operator

The new SARITOR is designed around the operator, with numerous features to make spraying safer, more precise, and less fatiguing.

A large, quiet, climate controlled, and pressurised Category 4 cab offers superb visibility to the front as well as back over the boom, while ISOBUS connectivity allows a wide choice of controllers.

Filling and cleaning is all managed from the single WorkZone, which includes FastFill connections and TurboFiller, as well as Ground Control Console for managing valves, pumps, rinsing and more.

Core strength

The chassis is made from high tensile steel (DOMEX® Swedish steel) to provide low weight, strength and flexibility. The U shape chassis rails with bolted cross members are a technology derived from the heavy vehicles industry and offer incredible flexibility.

All the main components like engine, main tank, RinseTank, pump etc. have been placed to optimize the weight distribution between front and rear axles.

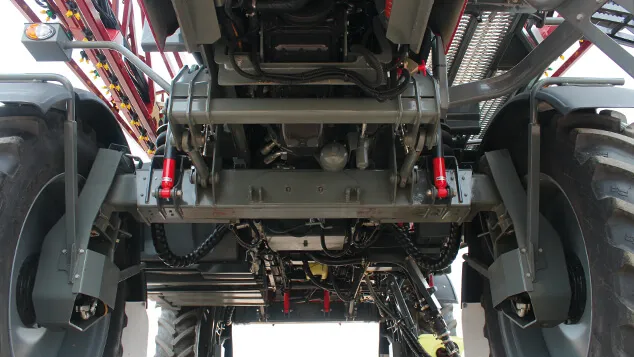

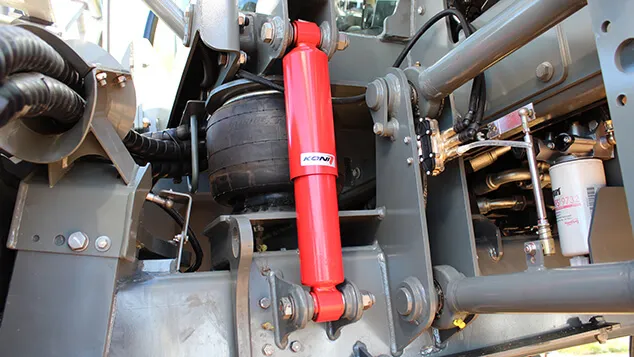

Suspension

Auto level air ride suspension combined with the flexible high strength chassis delivers an enviable ride for the operator.

Front axle suspension Independent ride level air bag suspension with two heavy-duty shock absorbers provides exceptional ride and performance.

Rear axle suspension The heavy-duty trailing link-arm suspended rear axle is equipped with independent air bag suspension for smooth ride and performance.

Axle track width

Quick and easy hydraulic track width adjustment for on road transport or in field operation. On-the-go adjustment Individual 3 to 4 m adjustable axles suit a variety of row crop applications and provides enhancing boom stability. Powerful A hydraulic cylinder is protected inside each axle and provides smooth and immediate adjustment.

4-wheel drive / 2-wheel steering

The 4WD hydrostatic transmissions are optimised for electro-hydraulic control and are coupled to intelligent electronics using the Sauer graphics terminal DP 250. The intelligent electronics are integrated into the Cummins “CAN” communication platform to ensure the engine power is optimised to the wheel motor torque which delivers smooth performance. The wheel motor output is matched to the engine torque, optimising fuel efficiency and the transmission operating pressure.

Turning circle

The SARITOR 62 Active is ideal for broadacre and row crop applications. With a turning radius 6.53 m, SARITOR is designed to be as manoeuverable as possible to prevent crop damage in the headlands.

The turning radius is measured to the center of the inner wheel at 4.3 m track width. The wheel base of the SARITOR is 4.26 m ensuring a stable platform when spraying in rough terrain.

Surface treatment

The chassis, the boom and all other steel parts have been pre-treated with Oxsilan followed by a high-quality coating of powder paint. This treatment provides outstanding protection against corrosion from both chemicals and harsh weather conditions. The high-technology surface treatment contains 13 treatments, including an Oxsilan pre-treatment and powder coat painting of all major components. Together with the Delta/Magni treatment of nuts, bolts and other items, we supply high corrosion protection of our products.

Access to engine

Service and maintenance of the SARITOR self-propelled sprayer is simple and practical. The bonnet is opened with a hydraulic hand pump, and gives easy access to the main engine components.

Checking and maintaining the various filters and oil level and is easily done. (Oil change is required every 250 working hours.) The fuel tank is also simple to access, on the right-hand side of the sprayer. Fuel capacity for the Cummins diesel engine is 600 litres.

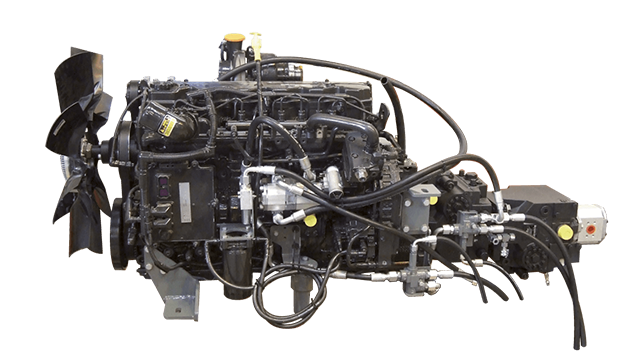

Engine

The new Tier 3 compliant Cummins QSB 6.7 diesel engine takes you to a whole new level of power, versatility and emissions control. It achieves Tier 3/Stage IIIA compliance with in-cylinder technology that maintains a compact, simple and cost-effective powerplant.

The QSB 6.7 offers major enhancements that makes the SARITOR work harder, smarter, quieter and longer…every time. The engine is power rated to 300 hp (223 kW) with charge air cooling and turbo charging for optimum performance.

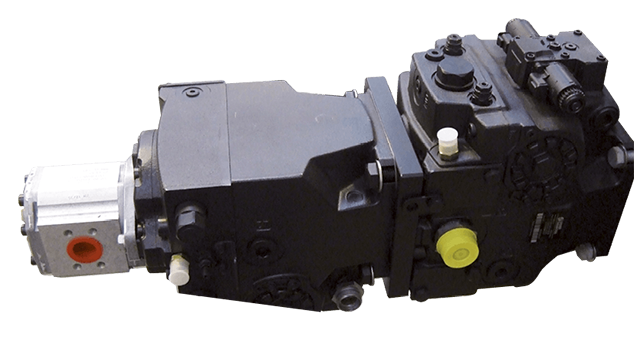

Transmission

4WD hydrostatic transmission Designed to provide intelligent drive management for your self-propelled sprayer, the Sauer-Danfoss H1 Transmission delivers versatile performance with reduced fuel consumption and improved operator comfort. Sauer-Danfoss H1 transmission pumps minimise controller and charge pump losses, which helps maximise available engine power at the wheels. In addition the Sauer-Danfoss H1 bent axis wheel motors offer significant overall efficiency and an extremely low pressure drop in the motor’s fluid reservoirs.

Engine and transmission display

A high resolution multi-functional display terminal gives clear control the engine’s operation, as well as transmission and operator selected control choices. The system can be set to display metric or imperial units. The display provides continual updates of engine, transmission and sprayer status in graphical or digital form. It also doubles as a ‘fault display terminal’, which illuminates and stores drive system error codes for diagnosis and maintenance.

Access and platform

Easy access to the platform and cab is via the front facing heavy-duty ladder. It automatically folds up out of the way when the transmission is engaged and folds down again when ‘Park’ is selected. The ladder has 6 x 38 cm wide steps, each 20 cm deep, which provides safe and sturdy accesses to the platform and cab. The first step is approximately 56 cm off the ground.

The cab

The SARITOR 62 Active features a large cab that is uncluttered and provides a high level of comfort for long days of spraying. It is quiet and provides excellent an excellent view in frotn and over the boom, thanks to HARDI’s high-visibility three-pillar design. Climate control air conditioning and cab pressurisation is delivered through 10 roof and 2 floor outlets, which are all fully adjustable. Dust and carbon filter ensures good air quality circulation, while windscreen demist vents ensure the windows will never fog up. For the driver, a fully adjustbale air-ride seat with its own suspension ensures hours of fatique free spraying. The seat can be adjusted for weight, height, lumbar support, leg comfort and motion.

Set to spray

Everything you need is at your finger tips – all managed through aTopcon X35 touchscreen spray controller and display, and SprayCenter control console. The joystick puts all the vital driving and spraying control functions in one hand. Forward, reverse and braking are operated by pushing forward or pulling back on the control lever. Spray ON/OFF, section control, boom height and wing tilt functions are all managed via joystick buttons Secondary control functions are managed from the SprayCenter switches on the arm rest.

The SARITOR 62 Active WorkZone provides a safe, centralised position for loading, managing and cleaning the sprayer.

The Ground Control console provides easy management of electric motor drive valves for selecting Main or RinseTank, Venturi, pump ON/OFF, tank rinse nozzles, boom nozzle, engine rpm and agitation. LEDs identify which valve is in operation.

A 2″ or 3″ filtered FastFill coupling and ball valve that lowers for easy connection is standard. A hydraulic drive banjo trasnfer pump is also an option.

A locker is provided for storage.

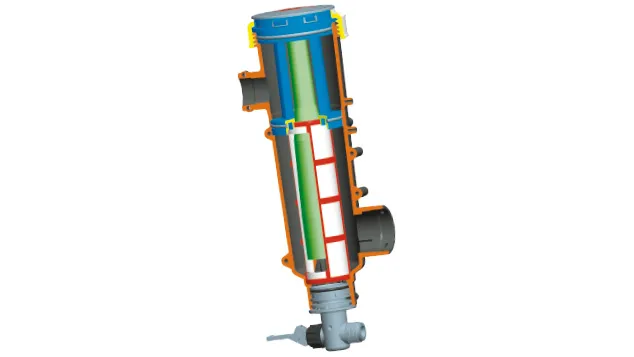

Cyclone Filter

The HARDI CycloneFilter is a unique pressure filter that uses a high-speed circular flow for powerful self-cleaning. This ‘cyclone’ action increases the speed of the liquid against the filter screen, making the self-cleaning action much more effective. The CycloneFilter also has a boost function allowing the filter to be flushed when needed. The filter’s design means it can be mounted upright, reducing the risk of spills and pressure loss during inspections.

TurboFiller

The HARDI TurboFiller can handle large quantities of powders and liquids. Its high capacity is achieved through a combination of high vacuum and liquid rotation produced by a TurboDeflector inside the hopper. High pressure water creates a powerful rotation inside the hopper, thoroughly mixing powder or liquid before it is sucked into the sprayer. Maximum capacity is achieved when the TurboFiller is more than half-filled with water. A spring-loaded bracket with transport lock lowers the TurboFiller to 95 cm above the ground for safe and easy use.

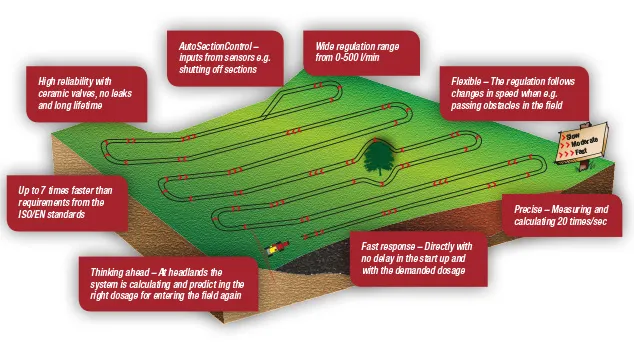

DynamicFluid4

The fluid system on SARITOR 62 Active is a new concept developed to obtain shorter response time and more precise application in the field. In a traditional fluid system, regulation is driven by what is already ‘historical’ data. For example if RPM is increased, the flow will immediately become too high at the nozzle. The spray computer will quickly regulate the excess pressure but the application rate will have been elevated in the meantime. The DynamicFluid4 system can calculate the impact of increasing RPMs and regulate the pressure instantly. This pro-active property is based on four sensors in the fluid system measuring RPM, regulation valve position, flow rate and pressure. Using new software and a unique ceramic regulation valve, DynamicFluid4 offers market-leading performance and precise rate control.

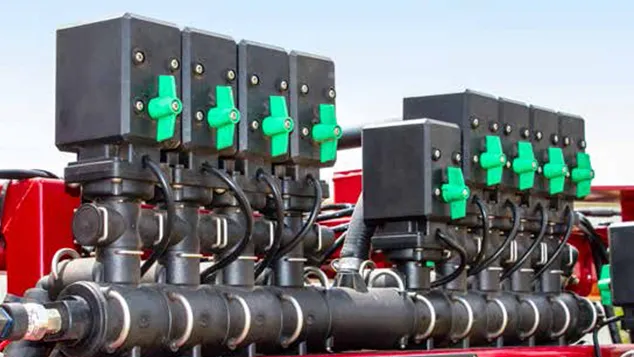

EFC boom section valves

The ElectricFastControl (EFC) is a modular system with a positive drive motor valve for each section and a single pressure dump valve, when all sections are switched to OFF. The section valves incorporate a pressure dump. When the section is switched to OFF, the pressure in the line to the nozzles is relieved. This results in instant shut-off at the nozzles. The EFC does not need any form of adjustment, e.g. pressure equalisation.

HC 9600

Saritor’s HC 9600 controller puts all the main spray functions at your fingertips. The 12.1” touchscreen and connected multi-function joystick work together to provide the highest levels of precision and performance. The HC 9600 is designed to be a powerful and all-inclusive precision farming tool. Features include guidance, data logging, application reports, GPS controlled spraying, automated steering and more!

Auto Section Control

AutoSectionControl automatically opens and closes boom section to avoid repeat spraying when passing over a sprayed area – such as in headland or while avoiding obstacles in the field. The HC9600 has AutoSectionControl as a standard feature and only needs to be connected to a GPS receiver. When spraying, the AutoSectionControl will automatically record the areas that have been sprayed then close sections as the boom passes back over the same ground.

HARDI Paragon Aluminium

When it comes to aluminium boom experience and know-how, HARDI is the market leader. With 30 years’ experience in optimising lighter, stronger and wider Pommier Aluminium boom set-ups we offer farmers real advantages in field performance, reliability and durability – as well as weight reduction. With aluminium boom wings weighing half as much as an equivalent steel structure, and our expertise in setting up Pommier Yaw dampening, the load and forces transferred to the centre during spraying are significantly reduced. Optional AutoHeight control sets a new benchmark in boom ride, maintaining a lower boom height which provides better drift control. A soft close feature also protects the boom when folding.

AutoTerrain

AutoTerrain gives SARITOR 62 Active unrivalled boom ride. AutoTerrain is a pre-emptive stability and auto height control system that deals with the causes of boom movement, allowing for a lower boom height and better drift control with near-zero risk of ground strike. The technology holds the boom at a set height above the soil or crop and follows contours like a magnet, regardless of terrain. AutoTerrain seamlessly monitors roll through the centre and the height of the boom off the ground 10 times every second. When a change is detected, AutoTerrain corrects the boom position relative to the ground contour by angling it through the centre pendulum.

TERRA FORCE boom

Built using heavy-duty steel, TERRA FORCE is available in sizes 36, 38, 40 and 42 m. The boom is designed to reduce turbulence over and around the nozzles. The three dimensional truss construction can withstand substantial yaw forces, which are absorbed through a hydraulically dampened parallelogram suspension system. With on-the-go stability control the dynamic boom centre can be set from the cab to suit the operating conditions. When the boom is open, positive locking ensures the wing components act as a single unit. Optional BoomPrime allows the boom to be primed with chemical before spraying is started or flushed.

Specifications

Tank | 4000 & 5000 |

Pumps – type | ACE 650 |

Pump capacity – l/min | 680 |

Boom type | TERRA FORCE |

For more information:

Scott Allen 0475 943 338 Email: sallen@centralagequipment.com.au

Vaughan Habner 0427 873 075 Email: vaughan@cumminsag.com.au

Mark Dickinson 0427 641 435 Email: mark@cumminsag.com.au

Jarrad Manners 0438 994 612 Email: jarrad@cumminsag.com.au

Comments